What Is a Narrow Belt Sorter?

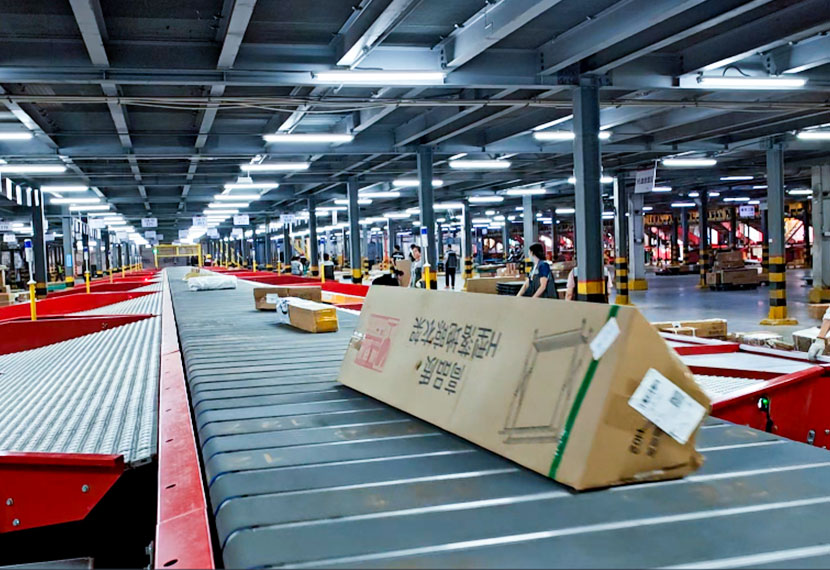

A narrow belt sorter is an automated sorting system that uses a series of narrow, parallel belts to transport and divert items to designated destinations based on criteria such as barcode data, weight, or shipping priority. Unlike bulkier sorting systems, narrow belt sorters are designed for space-constrained environments, making them ideal for smaller warehouses or facilities looking to maximize floor space. These systems employ pop-up rollers or diverters to redirect items to chutes or conveyors, ensuring high accuracy and efficiency.

Realkey narrow belt sorters, part of their Sorter Series (RKSORT), are engineered to handle a wide range of parcel sizes and types, from small envelopes to medium-sized packages, with seamless integration into warehouse management systems (WMS) for real-time tracking and analytics. By automating the sorting process, narrow belt sorters overcome the limitations of manual sorting, such as slow processing and high error rates, enabling businesses to meet tight delivery schedules and customer expectations.

Key Features of Realkey Narrow Belt Sorters

Realkey narrow belt sorters are designed for efficiency, reliability, and adaptability, making them a top choice for logistics leaders. Key features include:

- Compact Design: Optimized for space-constrained facilities, these sorters maximize throughput without requiring large footprints, ideal for urban warehouses.

- High Throughput: Capable of sorting thousands of items per hour, with some models reaching up to 6,000, ensuring rapid processing during peak periods.

- Precise Diversion: Pop-up rollers or belt diverters ensure accurate sorting to multiple destinations, minimizing errors and supporting complex routing needs.

- Versatile Handling: Suitable for a variety of parcel sizes, from small packets to medium boxes, accommodating diverse e-commerce and postal needs.

- Advanced Technology: Equipped with high-resolution CCD cameras for barcode scanning and AI-driven software for real-time optimization, ensuring precision and speed.

- Low Maintenance: Grease-free components and durable materials reduce downtime and maintenance costs, enhancing long-term reliability.

- Modular Integration: Easily integrates with existing systems, such as Realkey Conveyor Series (RKCONV) or Loader Series (RKLOAD), for seamless scalability.

Realkey commitment to OEM customization and rigorous quality control ensures their narrow belt sorters meet specific operational requirements, from small-scale facilities to high-volume hubs.

How Narrow Belt Sorters Work?

The operation of a narrow belt sorter combines mechanical efficiency with intelligent software. The process begins at the infeed stage, where items are loaded onto narrow belts, often using automated loaders like Realkey RKLOAD series. Sensors, including barcode scanners, weight scales, and dimensioning cameras, capture critical data about each item, such as its destination or priority.

The belts, arranged in parallel, transport items along a conveyor path. When an item reaches its designated chute, pop-up rollers or diverters activate to redirect it with precision, guided by real-time software calculations. This mechanism allows for high-speed, multi-directional sorting, with the ability to handle multiple destinations simultaneously.

Integration with WMS ensures real-time tracking, inventory updates, and predictive maintenance, with error rates typically below 0.1%. The compact design minimizes space usage while maintaining high throughput, making narrow belt sorters ideal for facilities where space is at a premium.

Benefits of Narrow Belt Sorters

Narrow belt sorters offer transformative benefits for warehouse operations, particularly in space-constrained environments. Here are the key advantages, backed by Realkey technology:

1. Space Efficiency: Their compact design maximizes floor space, allowing smaller warehouses to achieve high sorting capacity without costly expansions.

2. High-Speed Processing: Sorting thousands of items per hour, these systems reduce processing times by up to 80% compared to manual methods, critical for peak seasons like China’s “11.11” shopping festival.

3. Accuracy and Reliability: Advanced sensors and algorithms ensure near-perfect sorting precision, reducing misdeliveries and boosting customer satisfaction.

4. Cost Savings: By minimizing labor needs, businesses can lower staffing costs and reallocate workers to strategic tasks. Low-maintenance designs further reduce operational expenses.

5. Scalability: Modular designs allow for easy expansion, accommodating growing demand without major overhauls.

6. Enhanced Safety: Automation reduces manual handling of heavy items, lowering workplace injury risks.

7. Eco-Friendly Operations: Optimized sorting streamlines delivery routes, reducing fuel consumption and carbon emissions, aligning with sustainability goals.

These benefits deliver a rapid return on investment (ROI), often within 1-2 years, making narrow belt sorters a cost-effective solution for modern warehouses.

Applications Across Industries

Narrow belt sorters are versatile, serving a range of industries with unique sorting needs. Realkey solutions are particularly impactful in:

- E-Commerce: Handling diverse online orders, from small packets to medium-sized boxes, to meet tight delivery schedules.

- Postal and Express Delivery: Supporting high-volume sorting for partners like SF Express and China Post, especially during peak periods.

- Retail: Managing inventory and returns efficiently in space-constrained facilities.

- Third-Party Logistics (3PL): Providing customizable solutions for varied client requirements.

- Small-Scale Warehousing: Optimizing operations in urban or limited-space environments.

The compact footprint and versatility of Realkey narrow belt sorters make them ideal for both small and medium-sized operations.

Real-World Success Stories

Realkey narrow belt sorters have delivered measurable results for leading logistics providers. SF Express praised Realkey reliability during the 2020 COVID-19 disruptions, highlighting their ability to deliver stable equipment under challenging conditions. During the “11.11” shopping festival, China Post credited Realkey sorters with enhancing capacity and competitiveness through fast, accurate sorting.

Express Mail Service also commended Realkey professionalism, noting seamless collaboration and consistent quality improvements. With 5.0 ratings across testimonials, Realkey narrow belt sorters prove their value in high-pressure environments.

Why Choose RK Sort for Narrow Belt Sorters?

Realkey 12,000-square-meter factory and 60 R&D experts enable them to deliver innovative, high-quality solutions tailored to specific needs. Their focus on OEM customization, rigorous quality control, and end-to-end support—from design to maintenance—sets them apart from competitors. Industry updates, such as insights on peak-season equipment demands, keep clients informed and prepared.

Whether for a compact urban warehouse or a growing distribution center, Realkey narrow belt sorters offer long-term reliability and efficiency.

The Future of Narrow Belt Sorting Technology

As logistics embraces advancements in AI, IoT, and robotics, narrow belt sorters will evolve to incorporate predictive analytics and self-optimizing systems, further enhancing efficiency. RK Sort is at the forefront, developing intelligent, sustainable solutions to meet future demands. Investing in these technologies today ensures businesses stay competitive in a rapidly changing market.

Conclusion

Narrow belt sorters are transforming warehouse logistics by delivering space-efficient, high-speed, and accurate sorting solutions. Realkey advanced systems empower businesses to optimize operations, reduce costs, and meet modern demands. By adopting these solutions, companies can enhance efficiency, improve customer satisfaction, and future-proof their supply chains. Visit www.rksort.com to explore how Realkey narrow belt sorters can elevate your logistics strategy.